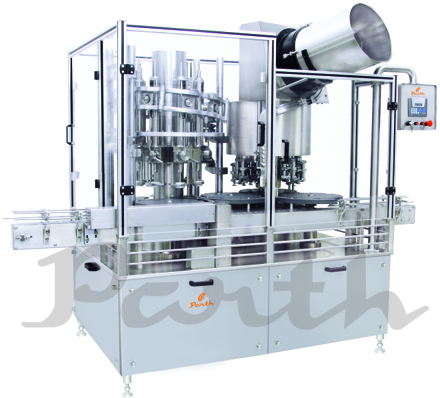

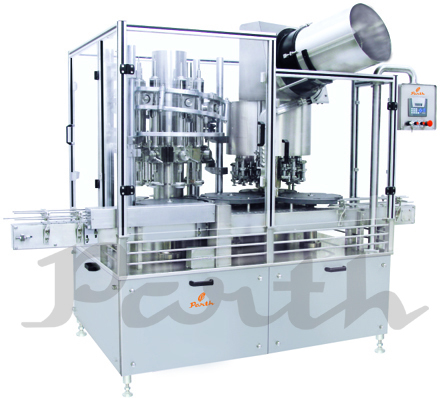

Chilly Sauce Filling Machine

Product Details:

- Type Other

- Material SS

- Computerized No

- Control Mode Automatic

- Click to View more

Chilly Sauce Filling Machine Price And Quantity

- 1 Unit

- 1450000 INR/Unit

Chilly Sauce Filling Machine Product Specifications

- Automatic

- No

- Other

- SS

Chilly Sauce Filling Machine Trade Information

- ICD Khodiyar - Ahmedabad / Nava sheva

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cheque

- Per Month

- Months

- Crate Packing, Base Packing, Export Worthy Wooden Packing

- Australia North America Eastern Europe Middle East Africa Central America South America Western Europe Asia

- All India

- CE, ISO 9001 : 2015, D & B

Product Description

Description:

High acknowledged owing to its versatile design and self-supported on leg with height adjustable system, the offered Automatic Rotary Piston Filling Cum Sealing Machine is manufactured with utmost precision on sturdy welded ms frame enclosed in stainless steel sheet and doors in order to facilitate the servicing of machine. Working on the principle of volumetric analysis with rotary motion, this machine is appreciated for its matt finish body.

Operation:

Fitted with containers moving on ss Slat conveyor, the filling nozzles through feed worm and Filling station consist of volumetric filling head. Having central rotating liquid reservoir tank, fed continuously with the liquid by external source. The offered In-feed liquid can be controlled in an automatic manner by sensing the liquid level in the reservoir tank with the aid of float switch in order to actuate pneumatically operated solenoid valve.

Fill volume adjustment can be incorporated by a screw that is used to change the volume of all the syringes simultaneously. In order to assure fine adjustment of individual syringe, it is provided on block of the individual syringe with the aid of mechanism. While the bottle pickup a cap from the delivery chute of cap, the body of the container is positioned below the rotating head.

Technical Specifications:

| Model | PRFS-16/8 |

| Output/Hour | 2400 to 4800 |

| Number of Syringe / head | 16 / 8 |

| Direction of Movement | Left to Right |

| Fill Size | 30 ml to 200 ml |

| Electric Specification | Main Machine - 5 HP / 415Volts / 50 Hz. |

| Oriental Bowl - 0.5 HP / 415Volts / 50 Hz. | |

| Conveyor - 0.75 HP / 415 Volts / 50 Hz. | |

| Height of Conveyor | 910 mm to 960 mm Adjustable |

| Machine Dimensions | 3500 (L) x 1700 (W) x 2100 (H) |

| Case Dimensions | 3700 (L) x 1900 (W) x 2300 (H) |

| Net Weight | 3200 Kgs |

| Gross Weight | 3700 Kgs |

| Change parts required | (A) Container: Star Wheel, Back Guide, Feed Worm, Nozzle |

Input Specifications:

| Container Neck Diameter | Minimum 22 mm | | |

| Container Size | Round Shape | 22 mm to 100 mm | |

| Flat / Square | 15mm to 100 mm (Length) | ||

| Depends on bottle size, cap size and type of cap. | |||

Salient Features:

-

All Contact Parts SS 316 and Non Contact parts SS 304.

-

Cap Grip made out of SS 304

-

Single Operator for Two Operations.

-

Less Floor Area - as both the sections driven by one motor.

-

No Contamination - as immediate sealing of filled bottles.

-

Accuracy + 1% accuracy due to piston dozing principle.

-

Centralized Volume Adjustment System- no down time in volume settings.

-

No Bottle No Fill for Individual head, hence no spillages.

-

Fewer Caps in chute, automatically stop the Machine.

-

Additional sensors for minimum and maximum level of cap in chute which automatically start and stop rotary cap feeder to avoid damage of caps during rotation and waste of energy.

-

Better finish imported polished, laminated S.S. hairlined pre-finished sheet used.

-

Separate variable drive to control speed of conveyor.

-

Electronic liquid level controller and pneumatically controlled control valve.

-

Drip trays under the conveyor.

-

Self Lubricating UHMW - PE Guide profile for Low friction wear surface, smooth and noiseless conveying.

-

Universal Coupling for quick and easy setting of In-feed worm.

-

Safety Guard for Operation and Protection.

-

Electronic Sensor at out feed for Bottle Jamming.

Features in PLC base Operations (Optional)

-

All operational controls through PLC.

-

Fault Indications.

-

Help Menu.

-

Auto / Manual operational mode.

-

Auto rejection system.

-

10 Recipes according to operation.

-

Various Alarms.

-

Production / Batch counter.

-

Multi level password security.

-

Guard Inter locking.

Optional Features:

-

Motorized Volume adjustable system.

-

Motorized height adjustable system for sealing system.

-

Automatic conveyor chain washing system.

-

Cap elevator for automatic cap feeding in cap feeder.

-

Nitrogen purging.

| Utility Requirement: | | |

| Electrical supply | 3 Phase + Neutral + Earthing | |

| Electrical load | 3 KW | |

| Air Pressure: Minimum | 6 bar pressure 0.5 CFM | |

Specification

| Capacity (pouch per hour) | 500-1000 |

| Pouch Length | Bottle/Container packing |

| Electric Load | 3 + 0.25 + 0.5 HP |

| Material | Stainless Steel |

| Power Consumption | 3 + 0.25 + 0.5 HP |

| Capacity | Customise |

Other Products in 'Rotary Vacuumetric Filling Machine ' category

|

PARTH ENGINEERS & CONSULTANT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS