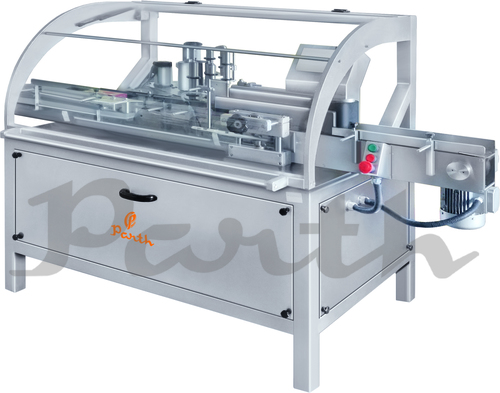

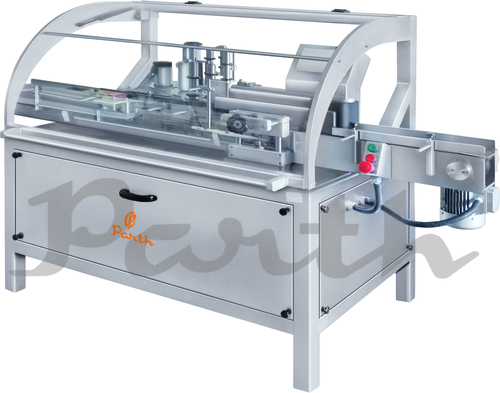

Double Side Labelling Machine

Product Details:

Double Side Labelling Machine Price And Quantity

- 650000 INR/Unit

- 1 Unit

Double Side Labelling Machine Trade Information

- ICD Khodiyar - Ahmedabad / Nava sheva

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cheque

- As per Requirement Per Month

- As per Requirement Months

- Crate Packing, Base Packing, Export Worthy Wooden Packing

- Western Europe Africa Central America Eastern Europe Middle East South America Asia North America Australia

- All India

- CE, ISO 9001 : 2015, D & B

Product Description

Description:

Having user friendly Sensing design for applying front and back labels on flat/oval/square shape containers, the machine offered by us is suitable for incorporates servo control label dispensing system or latest micro processor control.

Operation:

Empty or sealed bottle received from the last operation through Conveyor and one bottle separator attachment is provided in order to separate the bottle from continuous movement. Fitted with two pressing device on conveyor in order to straight and positioned the bottle, it is come up with a sensor to sense the product for operating steeper to release label. To remove the air between label & bottle, the gap sensor gives command in order to stop the stepper during releasing of label provision of brush to press the label. Two label applicators are widely used for double side labeling and single label applicator is used for single labeling.

| Technical Specification: | |

| Product | Flat Bottle (Single or Double Side) (We also supply attachment for round Bottle labeling) |

| Label size | 20mm to 200mm Width x 20mm to 300mm Height (for specific requirement) |

| Maximum output | Upto 240 bottles/minute depend on label size & products |

| Conveyor Motor | 230 Volts/AC/50 Hz Motor 0.5 HP Variable Speed |

| Stepper Motor | 60 Kg. |

| Label gap | 3mm between labels |

| Label Roll Dia. | 300 mm |

| Core Dia. | 75/76 mm |

| Machine power | 230 Volts/AC/50Hz Single Phase |

| Machine panel | Micro Processor Control Unit Programmable or Servo based PLC |

| Sensor | Sick Germany or Banner use or SunX Make. |

| Printer | Ink type Coder/Cassette type Coder / hot foil /inkjet |

| Machine Dimensions | 2500 mm Length x 700mm Width x 1500mm Height Conveyor 800mm Height 50mm adjustable Legs |

| Case Dimensions | 2700mm Length x 900 mm Width x 1700mm Height |

| Net Wt. | |

| Gross Wt. |

Salient Features:

- No Label Data Input/retrievals require for any Label Size

- No Change Parts for Label size,

- Synchronized speed of Label Dispensing,

- Conveyor and Top Hold Belt System

- Virtually Maintenance free machine

- Easy to change label application height

- User Friendly Label Placing Adjustments

- Self Protected against Voltage Fluctuations

- Suitable for On-Line Inkjet and Contact Coding System

- Suitable for Partial, Full Wrap Around and Overlap Labeling

- Built In A.C. Variable Frequency Drive System.

- Fully Stainless Steel finishes Machine

- Label Roll Empty - Machine Stop System with Alarm

- Missing Label in Roll - Machine Stop System with Alarm

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it.

- Option of Contact Coder, Hot Foil Coder, HP Cartridge Coder and Inkjet Coder with various speed ranges available.

- Toughened Glass or Acrylic Safety Cabinet for Machine

- Tower Light showing the machine status / operation

- Colour or Mono Touch Screen with PLC for machine operation and showing various error messages and information on display

- Special Sensing system for checking missing label on product

- Low Compressed Air - Machine Stop with Alarm system for pneumatically operated coding system

- Vision System for checking Barcode, presence or absence of Coding or pharma code on labels

- Vision System with OCR system for checking coding on labels

- Online pneumatically operated product rejection system

Other Products in 'Labelling Machine' category

|

PARTH ENGINEERS & CONSULTANT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS